How we work

5 key factors for our custom packaging solutions

1. Storage requirements

2. Sales and usage scenarios

3. Sustainability

4. Cost-effectiveness

5. Aesthetic appeal

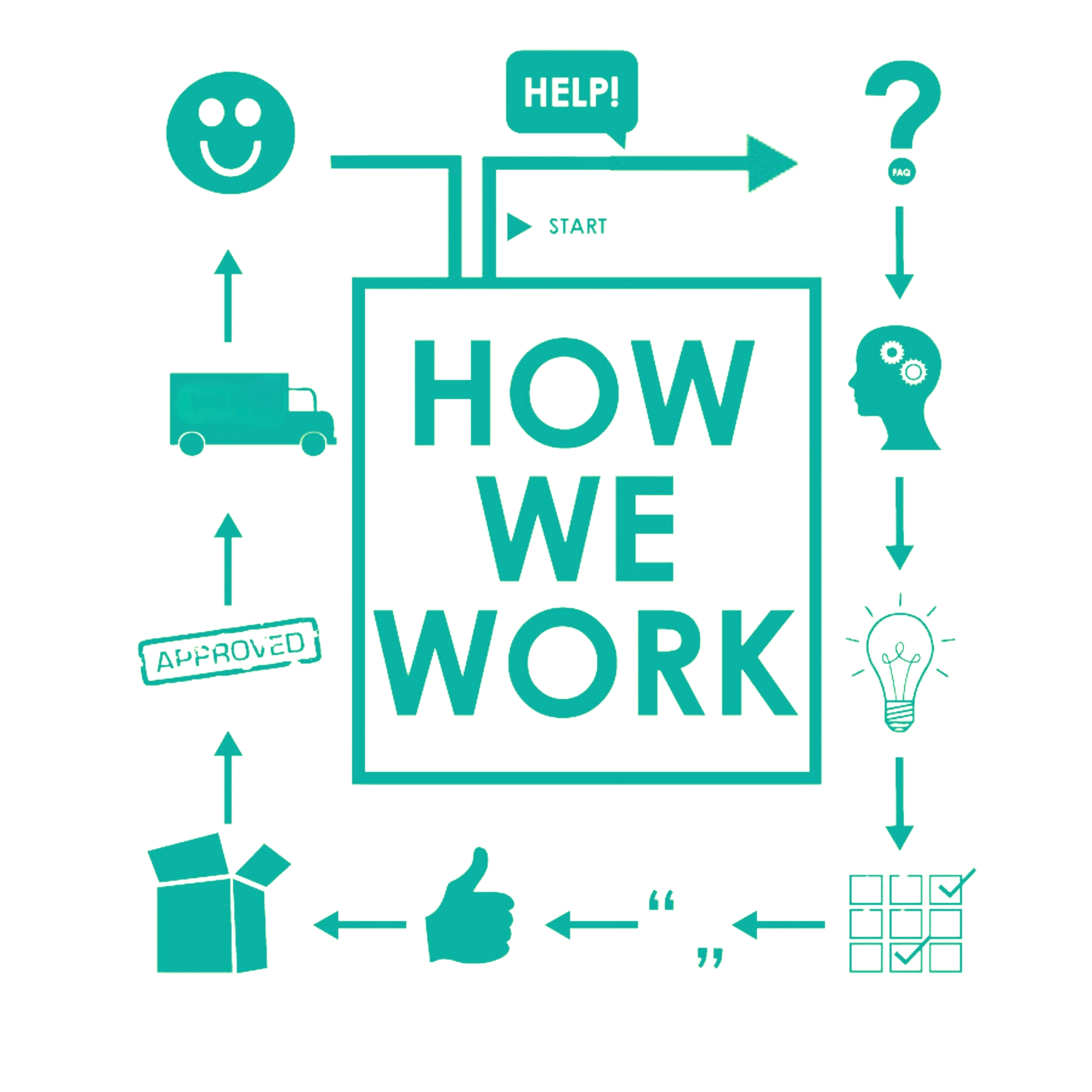

Our Custom packaging process

Consultation: The process begins with a consultation to understand the client’s needs, preferences, and budget. This includes discussing the product, target audience, and branding strategy.

Design Proposal: Based on the consultation, a design proposal is created. This includes sketches or digital mock-ups of the packaging design.

Feedback and Revision: The client reviews the design proposal and provides feedback. Necessary revisions are made based on this feedback.

Prototype Creation: Once the design is finalized, a prototype is created. This gives the client a tangible example of what the final product will look like.

Production: After the prototype is approved, production begins. This involves sourcing materials, printing, and assembling the packaging.

Quality Control: Each piece of packaging goes through a quality control process to ensure it meets the agreed-upon standards.

Shipment: Finally, the packaging is shipped to the client or directly to the distribution centers.

Packaging graphic design

Our in-house designers and partnered agencies craft innovative, eye-catching designs that not only elevate your brand but also resonate with your customers. Our expertise lies in understanding your products and translating it into a design that speaks volumes about your brand.